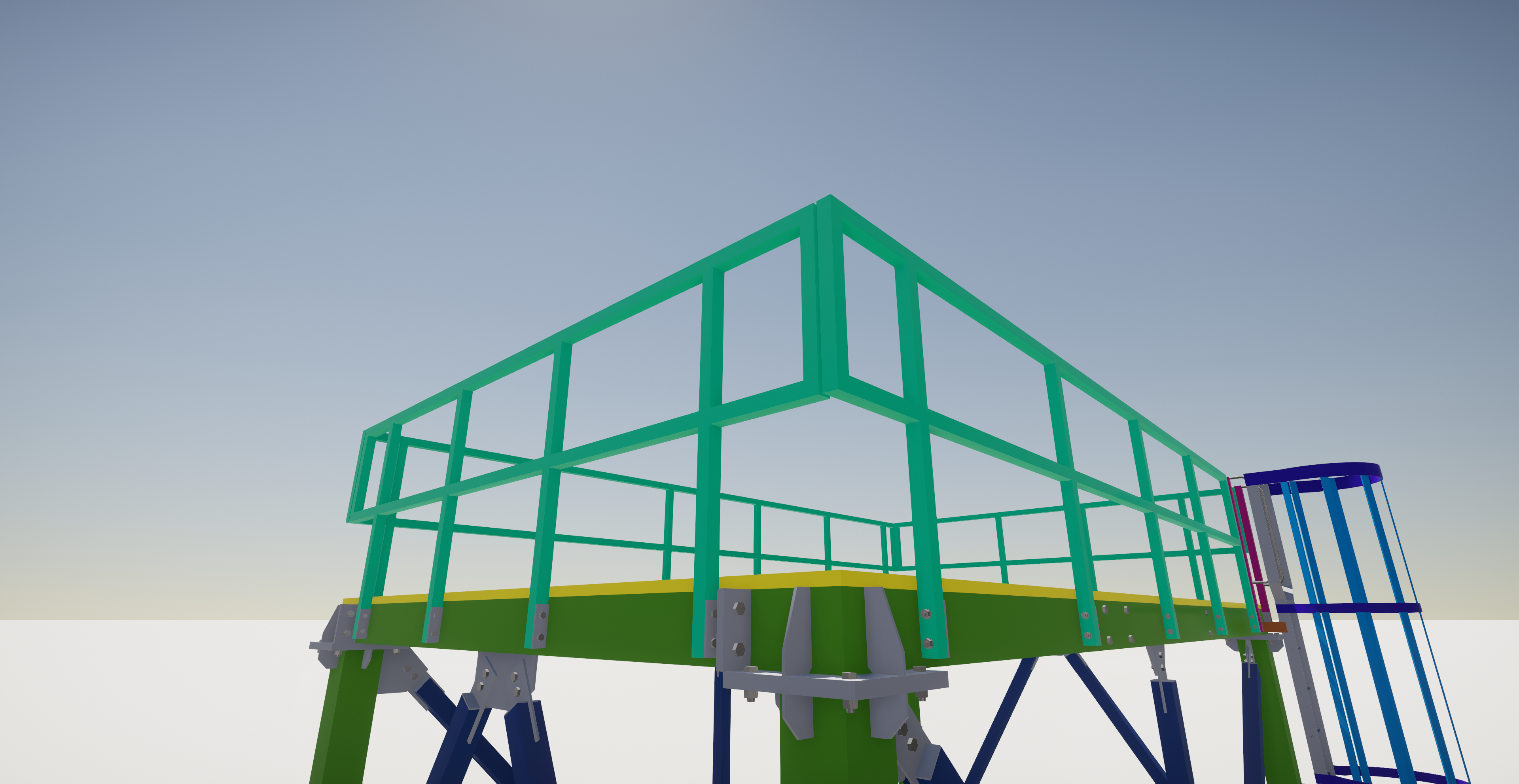

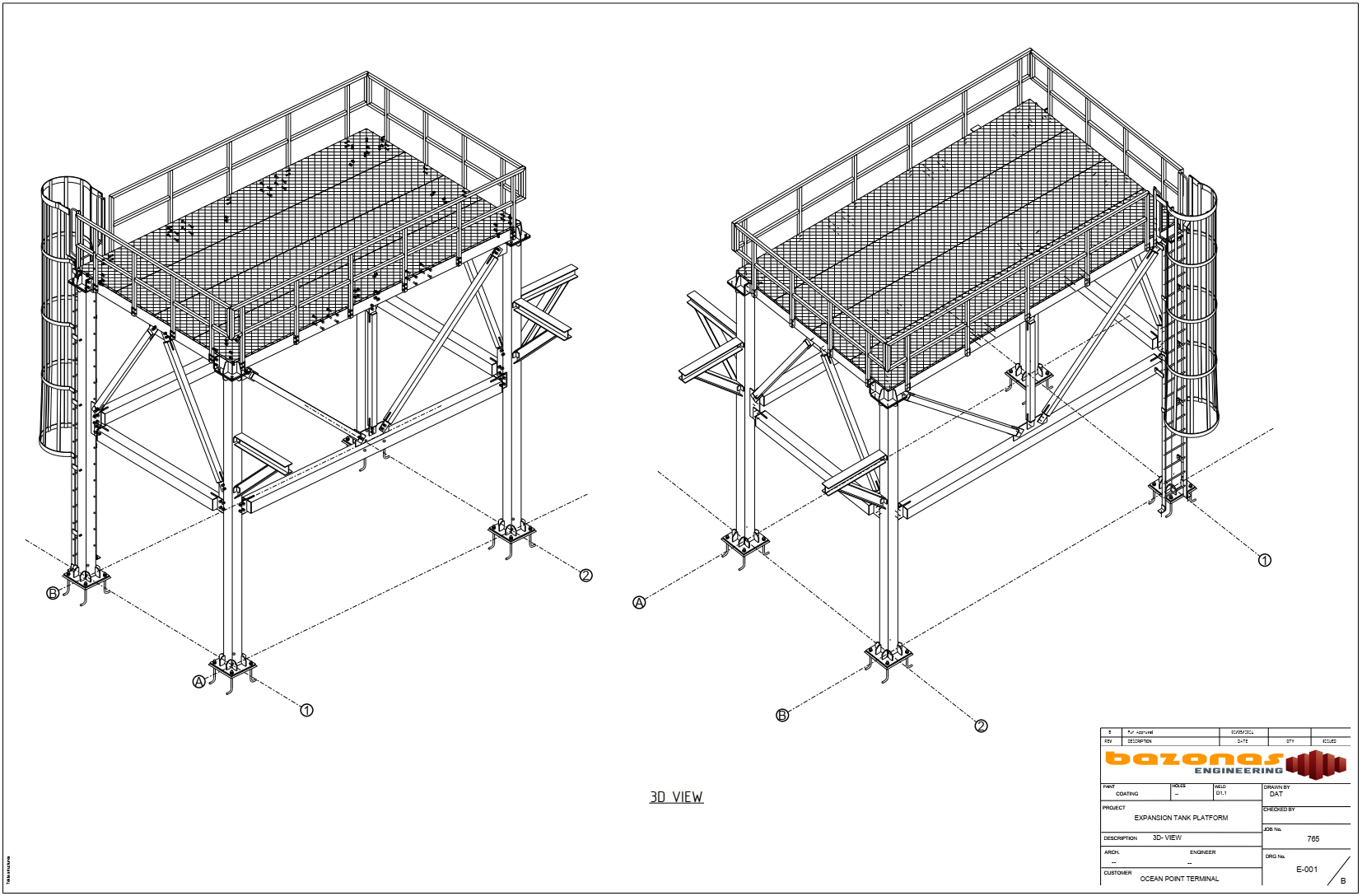

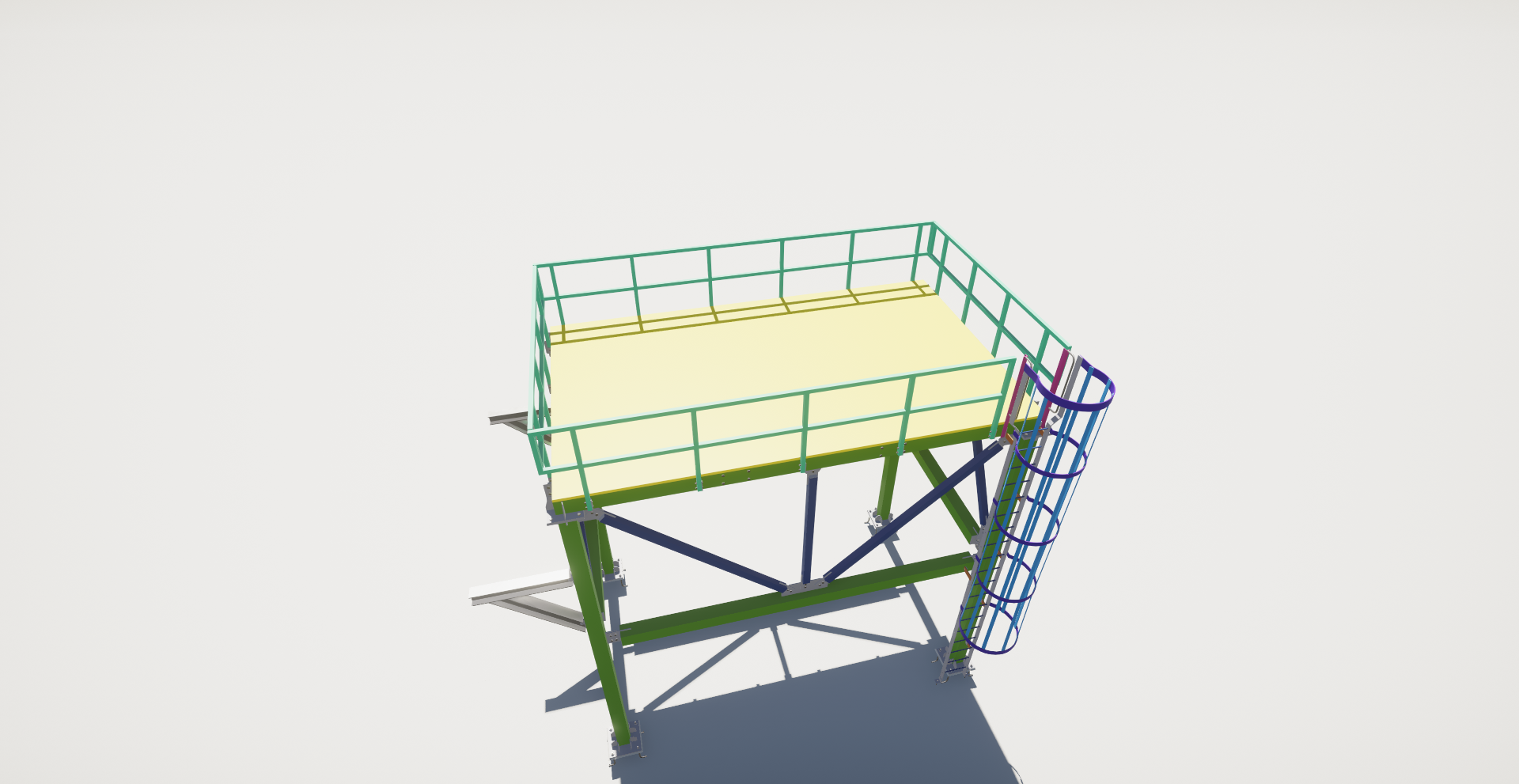

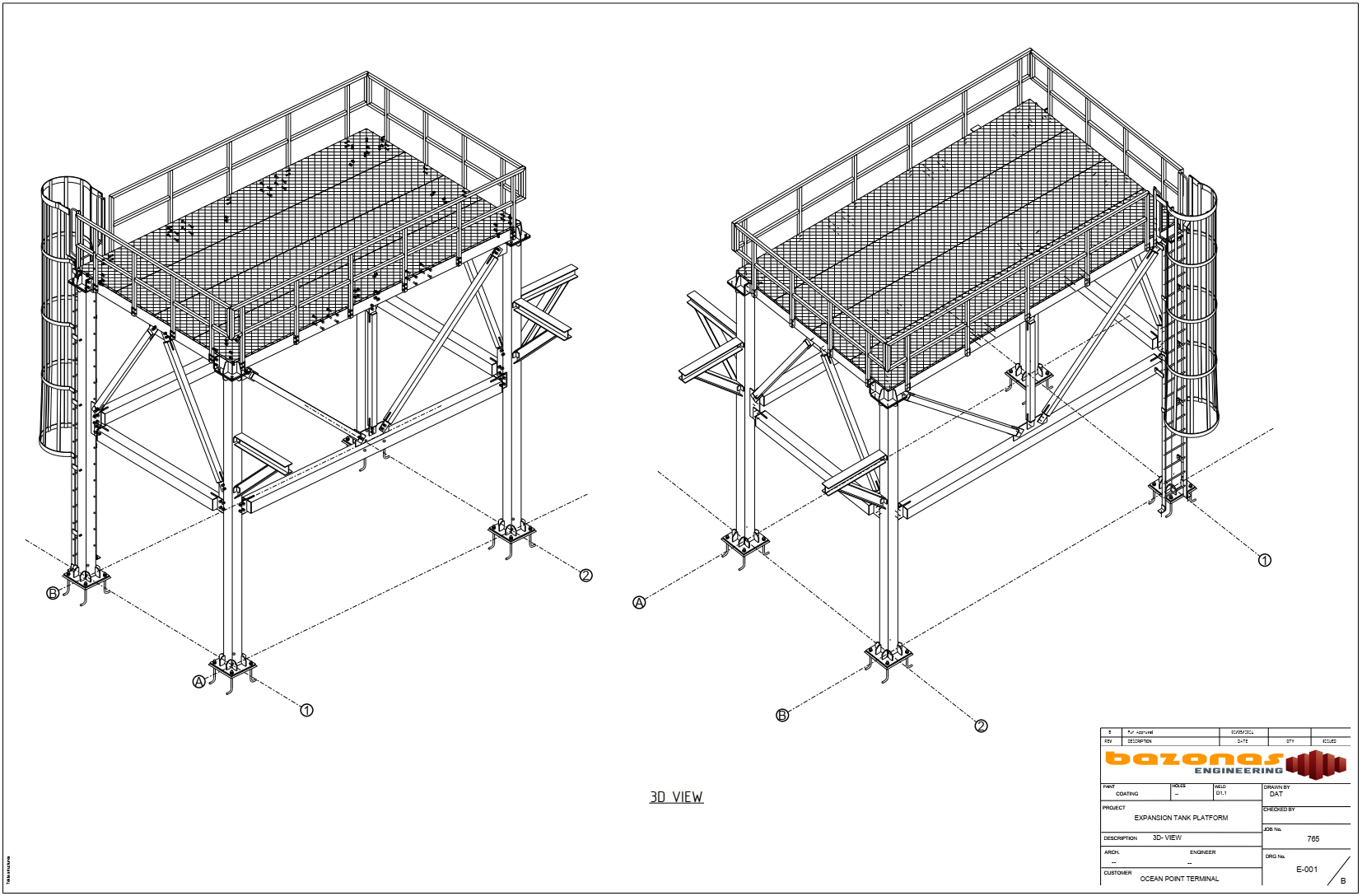

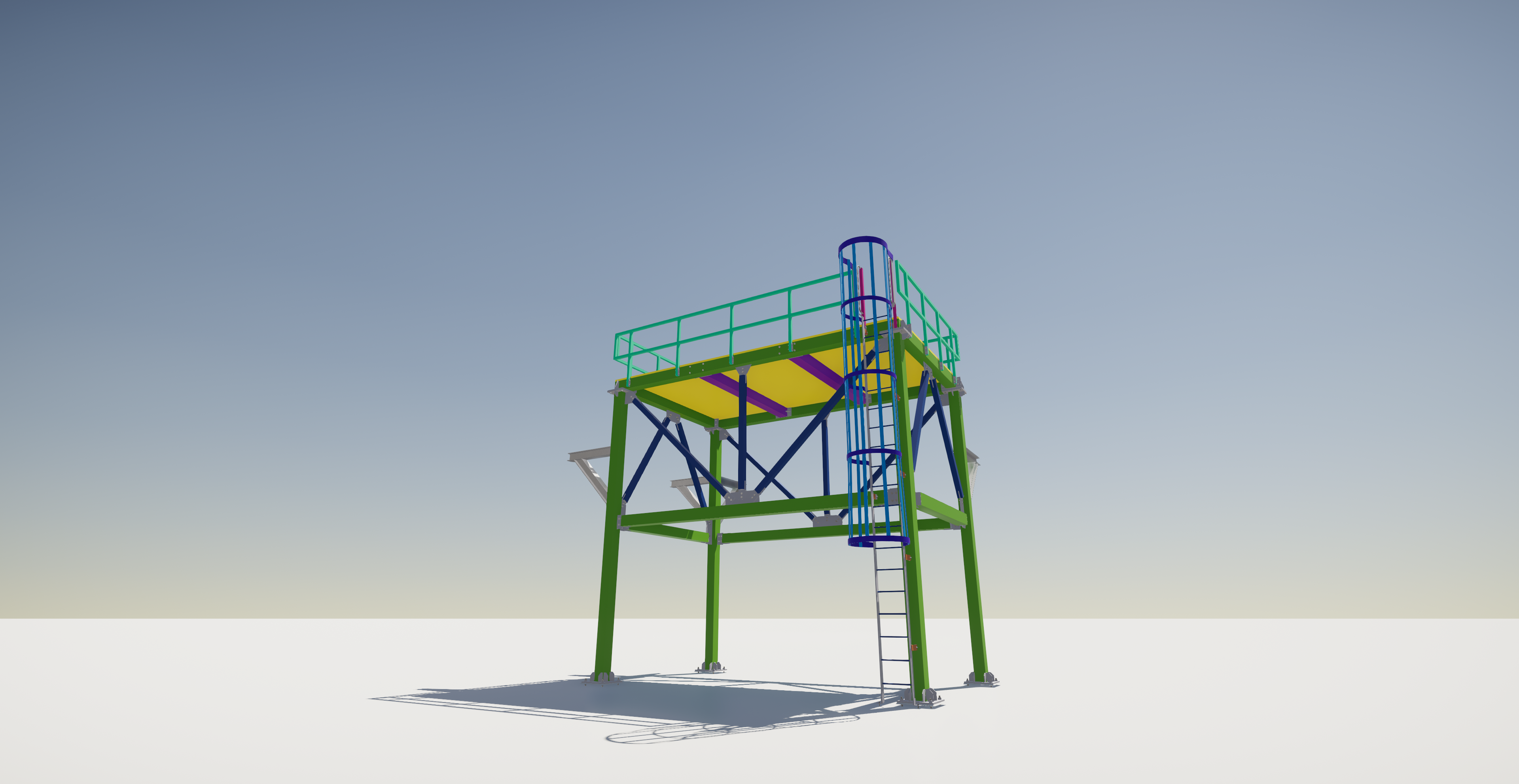

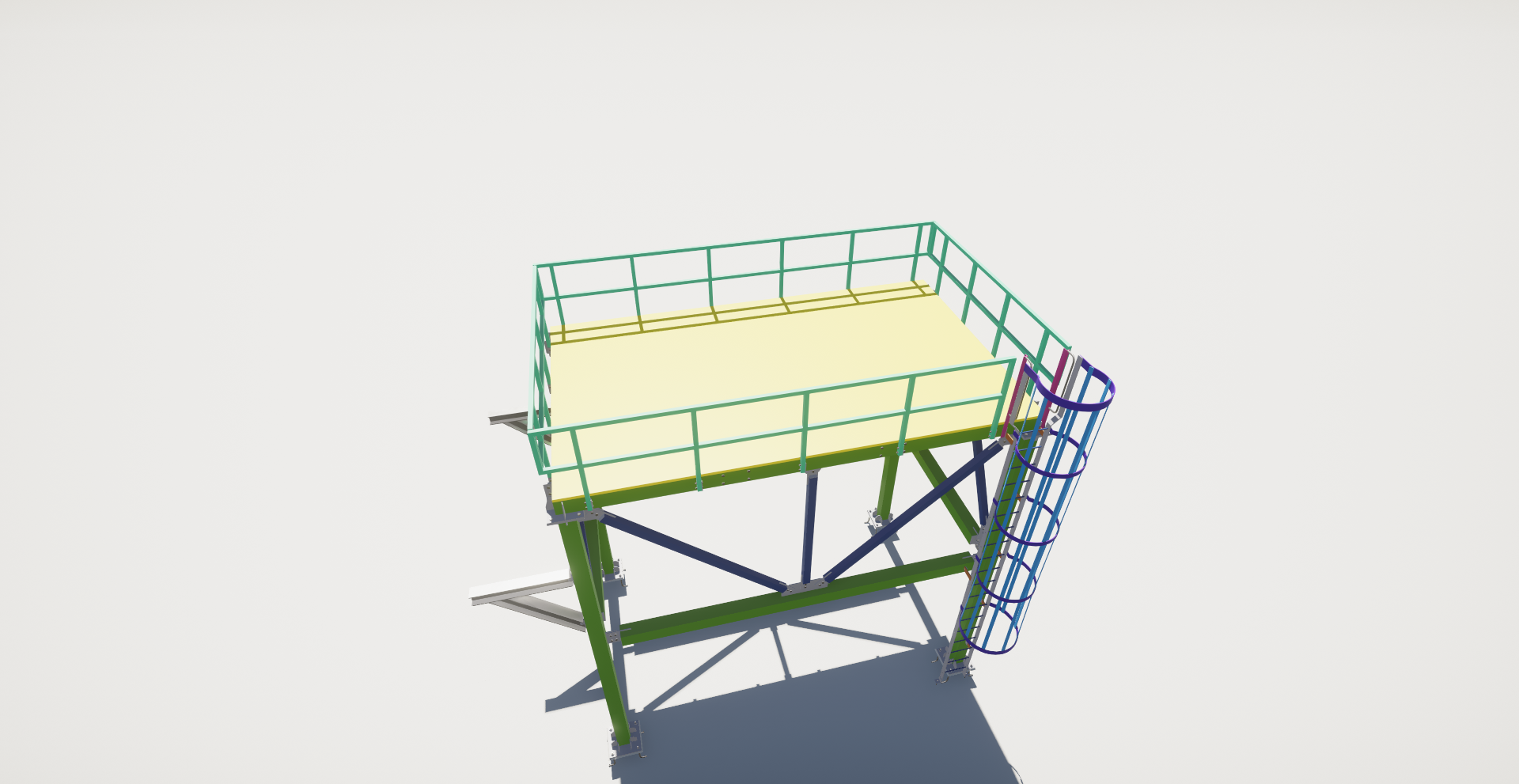

The EXPANSION TANK PLATFORM project is a specialized platform designed to accommodate a 2000-liter tank. This unique project requires modifications to the original customer design due to the current bracing system interfering with the pipeline. To meet this requirement, we have designed and implemented a new bracing system, ensuring no obstruction and complete compatibility with other elements at the site.